Careers

2025 Top High Purity Chemicals Trends and Market Insights

The demand for high purity chemicals is experiencing significant growth, driven by advancements in various industries such as pharmaceuticals, electronics, and specialty chemicals. According to a recent market analysis, the global high purity chemicals market is projected to reach USD X billion by 2025, expanding at a CAGR of Y% from 2023 to 2025. This surge is primarily attributed to the increasing need for specialized chemicals that meet stringent regulatory standards and performance requirements. As technologies evolve, the necessity for higher purity levels in chemical manufacturing becomes imperative, particularly in sectors where product integrity and performance are critical.

Moreover, the growing emphasis on sustainable and efficient manufacturing processes is further highlighting the importance of high purity chemicals. Industries are now focusing on improving their supply chains and reducing impurities to enhance product quality. Reports indicate that the electronic chemicals segment, in particular, is expected to witness robust growth due to the rise in demand for advanced semiconductor manufacturing, thereby emphasizing the need for ultra-high purity chemicals. As we delve into the trends and insights of the high purity chemicals market for 2025, it becomes clear that the confluence of technological advancements and industry requirements will shape the future landscape of chemical production and application.

Current State of High Purity Chemicals Market in 2025

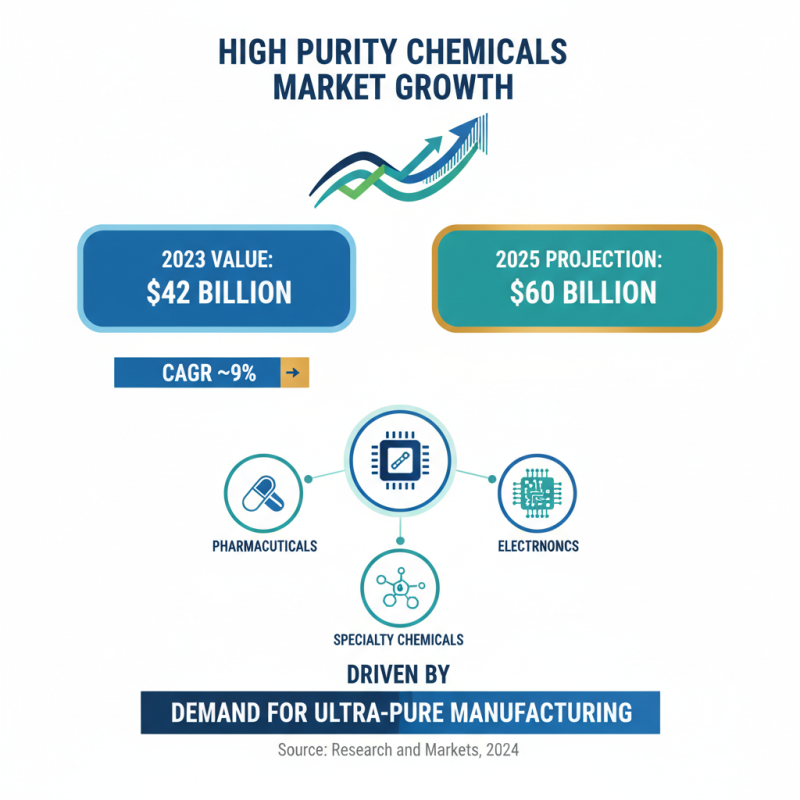

The high purity chemicals market is experiencing significant growth, driven by advancements in industries such as pharmaceuticals, electronics, and specialty chemicals. According to a recent market analysis by Research and Markets, the global high purity chemicals market was valued at approximately $42 billion in 2023 and is projected to reach nearly $60 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 9%. This surge is largely attributed to the rising demand for ultra-pure chemicals required in the manufacturing of semiconductors and other electronic devices, where even minute impurities can lead to product failure.

Amid the rapid technological evolution, the pharmaceutical sector remains a pivotal driver of this market. High purity solvents and reagents are essential for the synthesis of active pharmaceutical ingredients (APIs) and the development of new drugs. According to a report by Grand View Research, the pharmaceutical segment is expected to account for approximately 40% of the total high purity chemicals market by 2025. This trend is complemented by increasing regulatory requirements for quality and purity standards, resulting in manufacturers prioritizing high purity protocols to ensure compliance with stringent health and safety regulations.

Moreover, sustainability is becoming a critical focus for the high purity chemicals industry. As environmental regulations become more stringent, companies are leveraging green chemistry principles to produce high purity chemicals with reduced ecological footprints. This shift is not only improving public perception but is also aligning with the broader movement towards sustainable manufacturing practices, providing firms with a competitive advantage in the market. The growth of the high purity chemicals market is thus anticipated to enhance innovation while meeting the evolving demands of various sectors well into 2025 and beyond.

Key Trends Shaping the High Purity Chemicals Industry

The high purity chemicals industry is undergoing significant transformation driven by several key trends. One of the most prominent trends is the increasing demand for high-purity chemicals across various sectors, particularly in pharmaceuticals, electronics, and advanced materials. As industries demand more precise chemical compositions to enhance product performance, manufacturers are focusing on improving their purification processes and adopting cutting-edge technologies to meet these stringent specifications. This shift is accompanied by rising investments in research and development, aimed at innovating new methods for purity enhancement and quality assurance.

Another critical trend shaping the industry is the growing emphasis on sustainability and eco-friendliness. As environmental regulations become more stringent worldwide, companies are seeking to minimize their carbon footprint throughout the production process. This includes adopting green chemistry principles and investing in sustainable sourcing of raw materials. Additionally, there is an increasing shift towards the development of biodegradable and less hazardous high-purity chemicals that align with global sustainability goals. As a result, businesses that can effectively balance high purity with environmental responsibility are likely to gain a competitive edge in the evolving market landscape.

2025 Top High Purity Chemicals Trends and Market Insights

| Category | Market Size 2025 (USD Million) | Growth Rate (CAGR %) | Key Application |

|---|---|---|---|

| Electronic Chemicals | 4,500 | 6.5 | Semiconductors |

| Pharmaceuticals | 7,200 | 7.2 | Active Ingredients |

| Specialty Chemicals | 3,800 | 5.0 | Coatings |

| Food Additives | 2,000 | 4.5 | Enhancers & Preservatives |

| Chemical Reagents | 1,500 | 3.8 | Laboratory Use |

Innovations in Production Processes for High Purity Chemicals

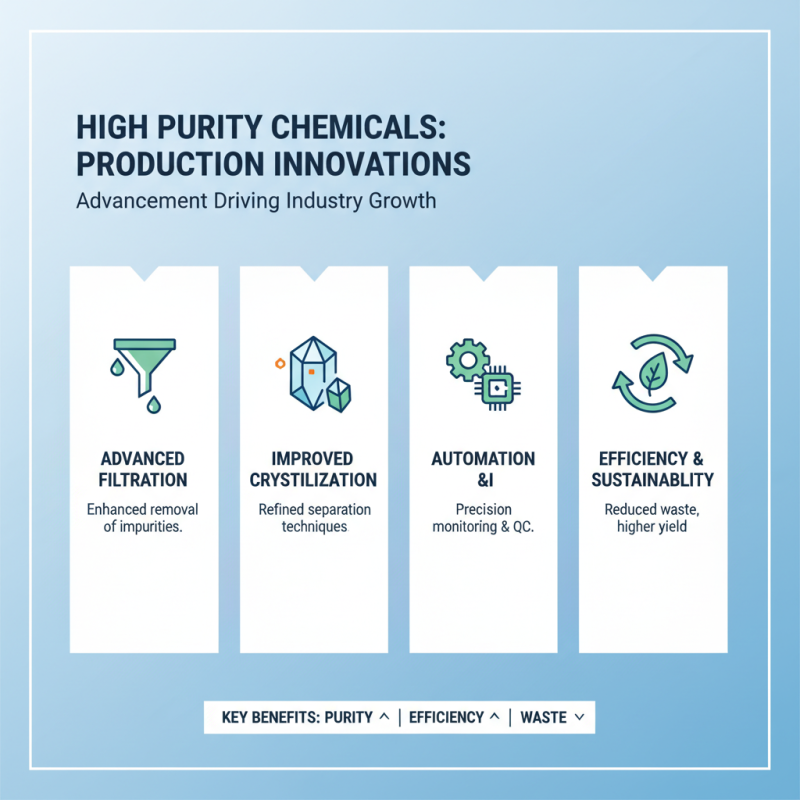

The high purity chemicals market is experiencing remarkable innovations in production processes, driving significant advancements in various industries. As demand for exceptionally pure chemicals grows, manufacturers are adopting cutting-edge technologies and methodologies to refine their production techniques. Key developments include advanced filtration systems, improved crystallization methods, and the integration of automation and AI in monitoring and quality control. These innovations not only enhance purity levels but also increase efficiency and reduce waste, aligning with sustainability goals.

Tips for improving production processes include investing in state-of-the-art purification equipment, which can greatly enhance the quality of the end product. Regular training sessions for staff on the latest technologies also ensure that the workforce remains adept and responsive to evolving industry standards. Moreover, collaboration with research institutions can yield insights that lead to breakthroughs in purity enhancement and process optimization.

As companies strive to meet increasingly stringent purity criteria, exploring novel separation techniques and optimizing existing processes will be crucial. Hydrodynamic cavitation and membrane separation technologies are making waves by providing more effective means to obtain high purity levels. Balancing innovation with regulatory compliance will be essential for sustaining growth in the high purity chemicals market while maintaining a commitment to safety and quality.

Regulatory Impact on High Purity Chemicals Market Dynamics

The regulatory landscape surrounding high purity chemicals is evolving rapidly and plays a crucial role in shaping market dynamics. With increasing scrutiny on chemical manufacturing processes and environmental impact, regulatory bodies are implementing stringent guidelines that manufacturers must adhere to. Compliance with these regulations not only ensures product safety and quality but also influences production costs and market entry strategies. As companies strive to meet these standards, there is a noticeable shift towards investment in advanced purification technologies and sustainable practices.

Moreover, the regulatory impact extends beyond compliance; it can also drive innovation in the high purity chemicals sector. As companies face pressure to align with new regulations, they are motivated to enhance their operational efficiencies and explore alternative raw materials. This proactive stance not only facilitates compliance but also positions them competitively in the market. The emphasis on sustainability and eco-friendly practices in new regulations is reshaping product development, urging manufacturers to consider the lifecycle of their chemicals in order to minimize environmental footprints. This trend indicates a broader shift towards a more responsible and forward-thinking approach within the high purity chemicals market.

Forecasting Future Demand and Supply Challenges in the Sector

As we move toward 2025, the high purity chemicals sector is expected to face significant demand and supply challenges. This industry, which encompasses chemicals with extremely low levels of contaminants, is vital for various applications, including electronics, pharmaceuticals, and biotechnology. Factors driving this demand include advancements in technology and the increasing need for specialized chemicals in high-tech industries. However, the supply chain remains fragile, impacted by geopolitical tensions, resource scarcity, and regulatory changes. Companies must navigate these uncertainties to ensure a stable supply of high purity chemicals.

Tips: To mitigate supply risks, businesses can adopt a multi-sourcing strategy. By diversifying their supplier base and considering alternative materials, companies can cushion themselves against shortages and price volatility. Investing in local suppliers may also reduce the impact of global disruptions, improving reliability and responsiveness.

Moreover, innovations in production processes are crucial for meeting future demand. As industries evolve, there will be a push for more sustainable and efficient manufacturing techniques. High purity chemical producers should prioritize research and development to enhance their processes, focusing on reducing waste and improving product quality. Collaborating with research institutions can also provide insights into emerging trends and technologies that may shape the future landscape of the chemicals market.

Related Posts

-

5 Best Practices for Chemical Industry Manufacturing Efficiency in 2023

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth

-

What is Unique Chemical Solutions and How Can They Benefit Your Industry

-

How to Choose the Best Chemical Products for Your Business in 2025

-

2025 How to Choose the Best Industrial and Chemical Solutions for Your Business

-

2025 How to Choose the Right Chemical Products for Your Business