Careers

2026 Best Practices in Chemical Industry Manufacturing for Sustainability

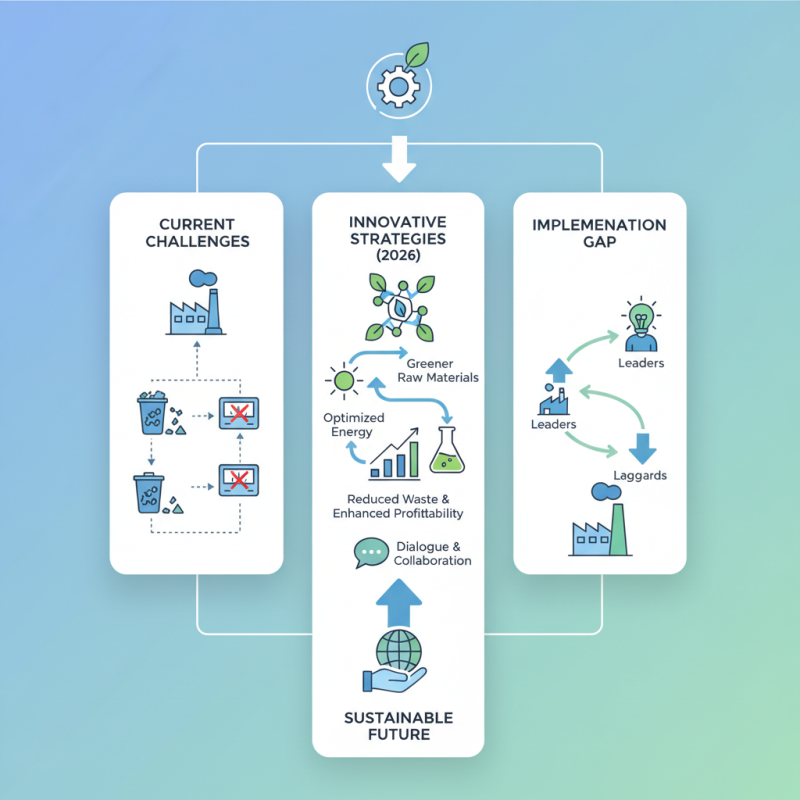

In the rapidly evolving landscape of chemical industry manufacturing, the drive towards sustainability is more crucial than ever. Dr. Emily Carter, a leading expert in this field, emphasizes, "Sustainability is not just an option; it’s a necessity for chemical firms." This sentiment reflects a broader shift in the industry. Manufacturers are now tasked with integrating efficient practices that also prioritize environmental stewardship.

As we approach 2026, the challenge intensifies. Companies often grapple with outdated methods that hinder their sustainability efforts. Innovative strategies must replace these practices. For instance, many companies are exploring greener raw materials and optimizing energy consumption. These changes promise not only to reduce waste but also to enhance profitability. However, not all manufacturers have adopted these strategies equally.

There remains a gap in implementation across the sector. While some leaders embrace change, others lag behind. The path to sustainable chemical industry manufacturing is fraught with obstacles. Acknowledging these shortcomings is vital for progress. Continued dialogue and collaboration can help bridge these divides. Ultimately, the commitment to sustainability must permeate every level of the chemical manufacturing process.

Best Practices in Chemical Industry for Sustainable Manufacturing

The chemical industry faces increasing pressure to adopt sustainable practices. Manufacturing processes must evolve to align with environmental goals. Studies show that by implementing eco-friendly technologies, companies can reduce energy consumption by up to 30%. This shift can significantly lower carbon footprints.

Waste management is crucial in sustainable manufacturing. Around 90% of waste in the chemical industry can potentially be recycled or reused. However, many firms struggle with effective waste reduction strategies. As a result, valuable resources are often lost. Emphasis on circular economy models can transform how materials are used, contributing to sustainability.

Moreover, improving social responsibility in chemical manufacturing is often overlooked. Employee wellbeing and community impact gaps can hinder progress. Reports indicate that companies that prioritize sustainability see a 10% increase in workforce satisfaction. Bridging this gap requires a cultural shift within organizations. The journey toward sustainability is complex but necessary for the industry's future.

2026 Best Practices in Chemical Industry Manufacturing for Sustainability

| Practice | Description | Benefits | Implementation Tools |

|---|---|---|---|

| Process Optimization | Enhancing manufacturing processes to reduce waste and improve efficiency. | Lower operational costs, reduced waste, and increased productivity. | Lean Manufacturing, Six Sigma. |

| Green Chemistry | Using principles of green chemistry to minimize the environmental impact. | Reduced toxic emissions and safer production methods. | Ecodesign tools, Material selection guides. |

| Energy Efficiency | Implementing energy-saving technologies and practices. | Decreased energy consumption and lower carbon footprint. | Energy audits, Smart grid technologies. |

| Waste Management | Developing strategies for reducing and recycling waste in production. | Minimized landfill use and lower disposal costs. | Waste audits, Recycle and Reuse protocols. |

| Sustainable Sourcing | Choosing raw materials that are sourced sustainably. | Enhanced supply chain resilience and reduced environmental impact. | Supplier audits, Certification systems. |

Innovative Technologies for Reducing Carbon Footprint in Chemicals

Innovative technologies are reshaping the chemical industry. A significant shift towards sustainability is underway. According to recent industry reports, companies can reduce their carbon footprint by up to 30% using advanced manufacturing processes.

One promising area is digitalization. The use of AI and machine learning helps optimize production. Predictive maintenance can decrease downtime, leading to energy savings. In addition, automation reduces human error and streamlines operations. However, the implementation cost can be a barrier for many smaller firms.

Green chemistry principles are gaining traction as well. These principles promote the design of chemical products that minimize waste and energy consumption. A study found that applying these principles in manufacturing could cut carbon emissions by nearly 50%. Yet, transitioning to greener methods often faces resistance. Workers may need retraining and the process can be slow. This reflects a need for ongoing collaboration and innovation within the industry.

Waste Minimization Strategies in Chemical Manufacturing Processes

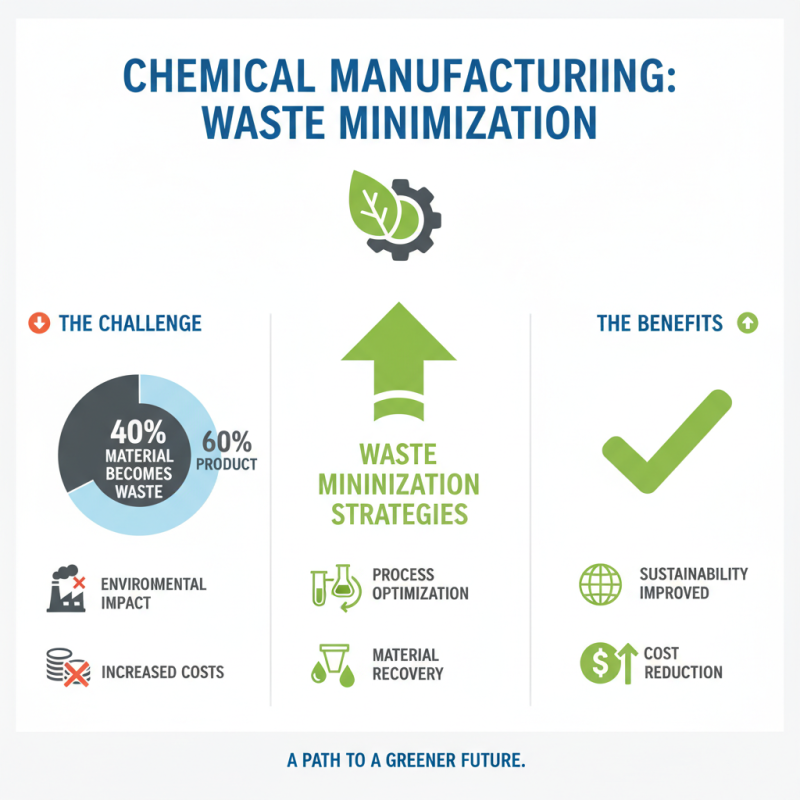

In chemical manufacturing, waste minimization is a critical aspect of sustainable practices. The industry produces significant waste, with estimates suggesting that around 40% of materials used in production become waste. This not only impacts the environment but also increases costs. Implementing effective waste minimization strategies can lead to substantial improvements.

One effective approach is the adoption of green chemistry principles. For instance, using safer solvents can reduce hazardous waste by up to 80%. Furthermore, process optimization techniques can help identify inefficiencies. By analyzing production processes, manufacturers can pinpoint stages where waste occurs. This can lead to a potential reduction of waste by 30%.

Education and training play vital roles too. Many employees lack awareness of waste reduction strategies. Companies that invest in training report up to 25% reduction in waste generation. Regular audits and monitoring can help maintain focus on minimizing waste. Yet, many facilities struggle with consistent implementation of these practices. Despite advancements, a gap remains between potential and actual waste reduction in the chemical industry.

Energy Efficiency Solutions for Sustainable Chemical Production

The push for energy efficiency in the chemical industry is crucial. Many facilities still waste energy in their production processes. Often, outdated equipment and practices hinder progress. For example, not all plants have adopted modern technologies that minimize energy consumption. This presents an area for improvement.

Implementing advanced energy management systems can lead to better outcomes. These systems help monitor usage continuously. Real-time data allows for adjustments that can significantly lower energy expenditure. Additionally, training staff on energy-saving techniques is essential. They can contribute to reducing waste and improving efficiency. However, many organizations neglect this aspect of their operations.

Investing in renewable energy sources is another step toward sustainability. Solar panels and wind turbines can supplement power needs. However, the initial costs can be daunting. Some companies hesitate to commit. This leads to missed opportunities for long-term savings. Achieving sustainability requires both innovative thinking and the willingness to change.

2026 Best Practices in Chemical Industry Manufacturing for Sustainability

This chart illustrates the energy efficiency solutions implemented in the chemical industry over the years, focusing on key areas such as process optimization, equipment upgrades, and renewable energy integration.

Sustainable Supply Chain Management in the Chemical Sector

In the chemical sector, sustainable supply chain management is essential. Companies are increasingly focusing on reducing their carbon footprints while maintaining efficiency. A recent report indicated that up to 80% of a product’s environmental impact occurs in its supply chain. This statistic highlights the importance of integrating sustainability into sourcing and logistics.

One effective strategy is to prioritize local suppliers. Sourcing materials closer to production facilities reduces transportation emissions significantly. Aim for a 50% increase in local sourcing to enhance sustainability. Moreover, engaging suppliers in sustainability practices fosters partnerships that align with eco-friendly goals. Regular assessments of suppliers’ environmental practices ensure they meet industry standards.

**Tip**: Consider implementing a supplier scorecard. This tool helps track sustainability metrics and encourages accountability.

It’s important to recognize that not all sustainable choices yield immediate financial gains. Some investments may require time to reveal benefits, leading to skepticism among stakeholders. Balancing economic viability with sustainable practices is a challenge many companies face. Emphasizing long-term benefits, rather than short-term profits, can shift this mindset. Companies must also remain adaptable to changing regulations and environmental standards.

Related Posts

-

5 Industrial and Chemical Solutions Driving 60% Efficiency in Manufacturing

-

How to Choose the Right Specialty Chemicals for Your Business Needs

-

How to Optimize Manufacturing Chemical Processes for Better Efficiency

-

Top 10 Essential Chemicals You Need to Know for Everyday Use

-

What is Unique Chemical Solutions and How Can They Benefit Your Industry

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth