Careers

Top 10 Tips for Choosing the Right Industrial Chemical Packaging Solutions

In the rapidly evolving field of industrial chemical packaging, selecting the right packaging solutions is crucial for ensuring safety, sustainability, and efficiency. According to industry expert Dr. Emily Richards, a leading authority in chemical packaging technologies, "The efficiency of an industrial chemical packaging solution can dramatically influence the integrity of the chemicals contained and the safety of the handling processes." This insight underscores the importance of making informed decisions when choosing packaging options that align with both regulatory requirements and operational needs.

As organizations continue to prioritize sustainability and compliance in their supply chains, understanding the nuances of industrial chemical packaging becomes increasingly vital. Factors such as material compatibility, environmental impact, and transport efficiency must be meticulously assessed. By carefully evaluating these considerations, businesses can optimize their packaging strategies, enhance safety measures, and ultimately drive their success in the marketplace. The following exploration of the top ten tips for choosing the right industrial chemical packaging solutions aims to provide essential guidance for professionals navigating this complex landscape.

Understanding the Importance of Industrial Chemical Packaging Solutions

Industrial chemical packaging solutions play a crucial role in ensuring the safe and effective transportation and storage of chemicals. These packages are designed to withstand various environmental conditions, thereby protecting the contents from contamination, spills, and degradation. The right packaging not only safeguards the chemical integrity but also enhances workplace safety by reducing the risk of leaks and accidents during handling. Understanding the various types of packaging materials and designs available is essential for businesses dealing with hazardous substances, as it directly impacts compliance with safety regulations and industry standards.

Moreover, effective industrial chemical packaging solutions contribute to operational efficiency. By selecting the appropriate packaging, companies can maximize storage space and streamline logistics, reducing transportation costs and improving supply chain management. Packaging that is easy to handle and adapt for various storage environments can facilitate faster turnaround times and improve overall productivity. Thus, investing time and consideration into packaging choices is not just about compliance and safety; it is integral to the broader operational strategy of a business dealing with chemicals.

Top 10 Tips for Choosing the Right Industrial Chemical Packaging Solutions

| Tip Number | Tip | Considerations | Advantages |

|---|---|---|---|

| 1 | Assess Compatibility | Chemical properties and packaging materials. | Prevents reactions and contamination. |

| 2 | Evaluate Regulatory Compliance | Local, national, and international regulations. | Avoids legal issues and penalties. |

| 3 | Consider Environmental Impact | Sustainability and recyclability of materials. | Reduces carbon footprint and improves image. |

| 4 | Choose Appropriate Size and Volume | Volume of chemicals and storage requirements. | Optimizes storage and handling efficiency. |

| 5 | Opt for Customized Solutions | Specific needs for unique chemicals. | Improves safety and usability. |

| 6 | Evaluate Cost-Effectiveness | Total cost of ownership vs. initial cost. | Maximizes value for money. |

| 7 | Prioritize Safety Features | Safety ratings and emergency procedures. | Minimizes risk of accidents. |

| 8 | Check for Availability and Supply Stability | Supplier reliability and stock levels. | Ensures consistent supply chain operations. |

| 9 | Seek User-Friendly Designs | Ease of use and handling for employees. | Enhances operational efficiency. |

| 10 | Review Vendor Support and Services | After-sales support and technical assistance. | Improves problem resolution and satisfaction. |

Evaluating Chemical Compatibility and Safety Requirements

When selecting industrial chemical packaging solutions, evaluating chemical compatibility and safety requirements is crucial. Proper packaging materials must withstand the specific chemicals they will contain, avoiding reactions that could lead to leaks or hazards. A comprehensive assessment of the chemical’s properties, including its reactivity, corrosiveness, and volatility, assists in choosing suitable materials. For instance, many chemicals react poorly with certain plastics or metals, making it essential to consult compatibility charts and safety data sheets during the selection process.

Additionally, it’s essential to understand the safety requirements associated with handling and transporting chemicals. Packaging must not only be sturdy but also compliant with relevant regulations to ensure safe storage and distribution. Consideration should be given to factors such as temperature fluctuations, exposure to elements, and potential for mechanical impacts. Implementing safety features, such as secondary containment and tamper-evident seals, adds an extra layer of protection for both the environment and personnel handling the materials.

One tip is to contact your packaging supplier for recommendations based on your specific chemical needs, ensuring that the packaging aligns with both compatibility and safety standards. Another important consideration is to invest in training for your staff regarding proper packaging handling techniques, reinforcing a culture of safety within your organization. These proactive measures can greatly reduce risks associated with chemical packaging and enhance overall operational safety.

Exploring Different Types of Packaging Materials Available

When selecting industrial chemical packaging solutions, understanding the various types of packaging materials is essential to ensure safety and efficacy. Commonly used materials include plastics, metal, and glass, each offering unique benefits tailored to specific chemical properties. Plastics, such as polyethylene and polypropylene, are lightweight and resistant to corrosion, making them ideal for storing a wide range of chemicals. Their flexibility in design allows for custom shapes and sizes, enhancing their usability across different industrial applications.

Metal containers, often made of steel or aluminum, provide a robust option for packaging chemicals that may react with plastic. They offer excellent barrier properties, protecting contents from environmental factors such as moisture and light. Glass packaging, while heavier and more fragile, is non-reactive and provides an impermeable barrier, making it suitable for highly sensitive substances. Understanding these materials' strengths and weaknesses is critical for businesses to select the appropriate packaging that aligns with the nature of the chemicals being stored and transported.

Assessing Regulatory Compliance and Environmental Considerations

When selecting industrial chemical packaging solutions, ensuring regulatory compliance and addressing environmental considerations are crucial aspects that cannot be overlooked. Regulatory compliance ensures that the packaging adheres to the relevant laws and guidelines established by governing bodies. This often includes understanding classifications for hazardous materials, adhering to labeling requirements, and ensuring that the materials used for packaging are appropriate for the specific chemicals. It is vital for businesses to conduct a thorough risk assessment to identify the necessary regulations applicable to their operations, as failure to comply can lead to legal consequences and potential hazards.

Equally important is the environmental impact of the packaging materials being utilized. As industries increasingly focus on sustainability, selecting eco-friendly packaging options contributes to a company’s overall environmental responsibility. This involves evaluating the life cycle of the packaging materials, including their sourcing, production, and after-use disposal. Using recyclable or biodegradable materials can significantly reduce environmental footprints, promote sustainable practices, and enhance corporate reputation. Additionally, organizations should remain informed about industry standards and emerging technologies that can lead to more sustainable packaging solutions, ensuring they take a proactive approach in aligning their operations with global sustainability goals.

Analyzing Cost-Effectiveness and Supply Chain Logistics

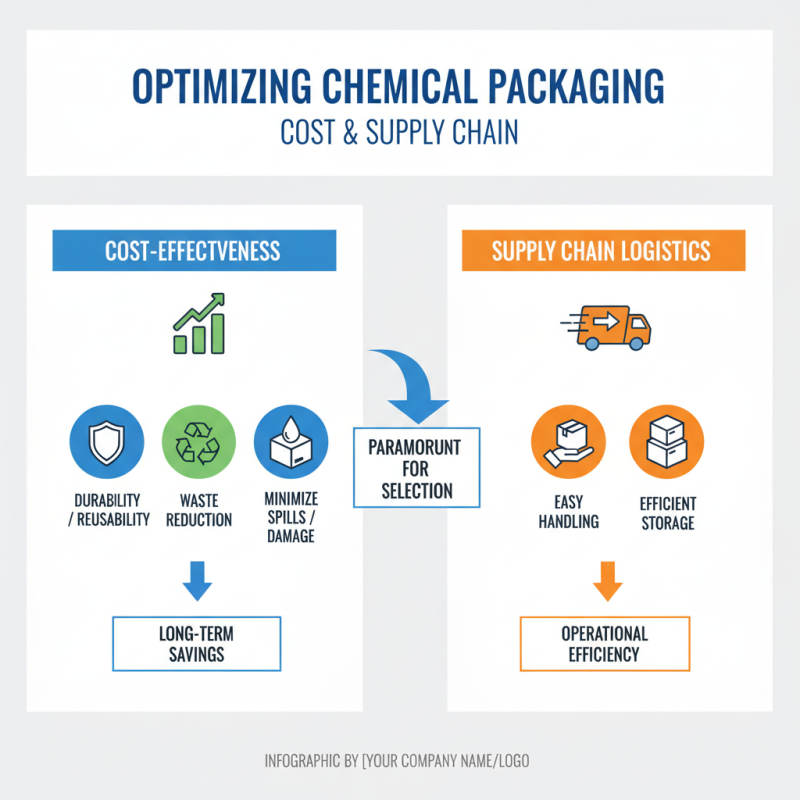

When selecting industrial chemical packaging solutions, analyzing cost-effectiveness and supply chain logistics is paramount. Cost-effectiveness involves not only the price of the packaging materials themselves but also the long-term implications of using these materials. This includes considering factors such as durability, reusability, and the potential for reducing waste. For example, choosing packaging that minimizes spills and damages during transit can lead to significant savings over time. Additionally, options that facilitate easy handling and storage can enhance operational efficiency, further improving the cost structure.

Supply chain logistics also play a critical role in the decision-making process. Effective packaging solutions should align with the entire supply chain, from storage facilities to transport methods, ensuring that they support seamless movement through each stage. Analyzing delivery times, transportation modes, and handling requirements can help identify packaging that optimizes logistics. Furthermore, considering the geographical distribution of suppliers and customers can lead to smarter choices, such as selecting local packaging suppliers to reduce transportation costs and lead times. Balancing these logistics with the overall cost-effectiveness of the packaging will ultimately determine the most suitable solution for the industry.

Related Posts

-

Top 10 Tips for Choosing the Right Manufacturing Chemicals for Your Business

-

How to Choose the Best Chemical Products for Your Business in 2025

-

What is Unique Chemical Solutions and How Can They Benefit Your Industry

-

Top 10 Innovations in Chemical Processing Driving Industry Efficiency in 2023

-

10 Essential Tips for Safely Handling Chemistry Chemicals in the Lab

-

Top 10 Industrial Chemical Packaging Solutions for Your Business Needs