Careers

10 Essential Tips for Safely Handling Pure Nitric Acid in Laboratories

Handling pure nitric acid in laboratory settings is a critical operation that requires rigorous adherence to safety protocols. As one of the most widely used reagents in both organic and inorganic chemistry, pure nitric acid is essential for various applications, including the synthesis of explosives, the manufacture of fertilizers, and the production of dyes. However, its corrosive nature poses significant risks to laboratory personnel. According to a report by the International Chemical Safety Card (ICSC), exposure to pure nitric acid can lead to serious health effects, highlighting the necessity for stringent safety measures.

Dr. Emily Carter, a leading expert in chemical safety at the National Institute of Industrial Chemistry, emphasizes the importance of proper handling techniques: "The safe management of pure nitric acid is not just a regulatory requirement, but a moral obligation to protect human health and the environment." To ensure the safety of laboratory personnel and maintain a secure working environment, it is vital to implement comprehensive training programs, utilize appropriate personal protective equipment (PPE), and establish clear emergency response protocols. By adhering to these guidelines, laboratories can significantly mitigate the risks associated with pure nitric acid and foster a culture of safety and responsibility in chemical handling.

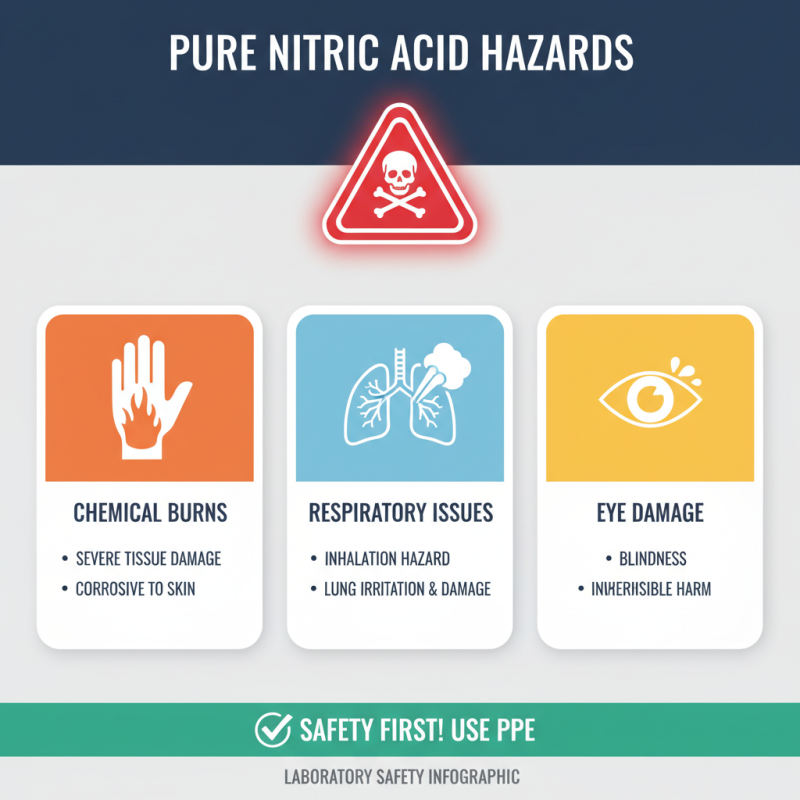

Understanding Pure Nitric Acid and Its Hazards in Laboratory Settings

Pure nitric acid is a highly corrosive and powerful oxidizing agent commonly used in laboratories for various applications, including chemical synthesis and analytical processes. Understanding its hazards is crucial for ensuring a safe working environment. Exposure to pure nitric acid can lead to severe chemical burns, respiratory issues, and eye damage, making it imperative for laboratory personnel to recognize the potential risks associated with its use.

When handling pure nitric acid, always prioritize safety. First, ensure that you are wearing appropriate personal protective equipment (PPE), including acid-resistant gloves, goggles, and a lab coat. Additionally, it's important to work in a well-ventilated area, preferably under a fume hood, to minimize inhalation risks. Another essential tip is to always add acid to water, not the other way around, to prevent exothermic reactions that can cause splattering.

Another vital consideration is proper storage and labeling. Nitric acid should be stored in a cool, dry place, away from incompatible substances such as organic materials and reducing agents. Clearly label all containers to prevent accidental misuse. Regularly inspect storage areas for leaks or damage, and ensure that safety data sheets are readily accessible to provide information on emergency procedures in case of an incident. Implementing these precautions will help mitigate the risks associated with handling pure nitric acid in laboratory settings.

Essential Personal Protective Equipment for Handling Nitric Acid Safely

When working with pure nitric acid in a laboratory setting, personal protective equipment (PPE) is crucial to ensure the safety of all personnel involved. The first line of defense against this highly corrosive substance includes the use of appropriate gloves, which should be made of materials specifically designed to resist chemical penetration. Nitrile or neoprene gloves are often recommended due to their superior protection against acids. Additionally, long sleeves or laboratory coats made of chemical-resistant materials are essential to shield the skin from any potential splashes.

In terms of eye protection, safety goggles or face shields are mandatory when handling nitric acid. Regular eyewear is not sufficient, as it may not provide the necessary seal and protection against airborne particles or splashes. Furthermore, a chemical-resistant apron can provide an added layer of safety for the torso, protecting against any accidental spills. It is also advisable to employ respiratory protection in situations where there may be a risk of inhaling vapors, especially in poorly ventilated areas. By integrating these essential pieces of PPE, laboratory personnel can significantly mitigate the risks associated with handling nitric acid.

10 Essential Tips for Safely Handling Pure Nitric Acid in Laboratories

This chart illustrates the importance of various personal protective equipment (PPE) when handling pure nitric acid in labs. Each bar represents the recommended level of use for each type of PPE, based on safety guidelines.

Proper Storage Protocols for Pure Nitric Acid in Laboratories

When working with pure nitric acid in laboratories, proper storage protocols are crucial to ensure safety and minimize risks. First, it's essential to store nitric acid in appropriate containers made of compatible materials, such as glass or certain plastics. Metal containers should generally be avoided due to the corrosive nature of nitric acid, which can lead to contamination or degradation of the container itself.

The storage area should be well-ventilated to prevent the accumulation of hazardous fumes, as nitric acid can release nitrogen dioxide, a toxic gas, when exposed to heat or instability.

Additionally, nitric acid should be kept in a cool, dry location away from direct sunlight and incompatible substances, such as organic materials or strong bases. This separation reduces the risk of accidental reactions that could lead to violent incidents. Clearly labeled storage locations and regular inspections of storage conditions can further enhance safety protocols. Furthermore, utilizing secondary containment systems, like acid cabinets or spill trays, ensures that any leaks or spills do not result in broader contamination, maintaining a safer laboratory environment for all personnel.

Best Practices for Spill Management and Emergency Response

When dealing with pure nitric acid in laboratories, effective spill management and emergency response protocols are crucial to ensuring safety and minimizing risks. According to the Occupational Safety and Health Administration (OSHA), spills involving hazardous substances like nitric acid require immediate action to mitigate potential harm. Laboratories should have spill kits readily available, equipped with neutralizing agents, absorbents, and appropriate personal protective equipment (PPE). A well-designed spill management plan can dramatically reduce the impact of accidents; studies indicate that 60% of laboratory incidents arise from inadequate spill containment measures.

In the event of a nitric acid spill, immediate evacuation and response should follow established protocols. The National Institute for Occupational Safety and Health (NIOSH) reports that exposure to nitric acid vapors can lead to severe respiratory issues and skin burns, underscoring the importance of timely action. First responders should be trained in the use of emergency equipment and the application of neutralizing agents, such as sodium bicarbonate or lime. Furthermore, laboratories should conduct regular drills to ensure all personnel are prepared to act swiftly and effectively in emergency scenarios, as preparedness has been shown to significantly reduce injury rates in chemical spills.

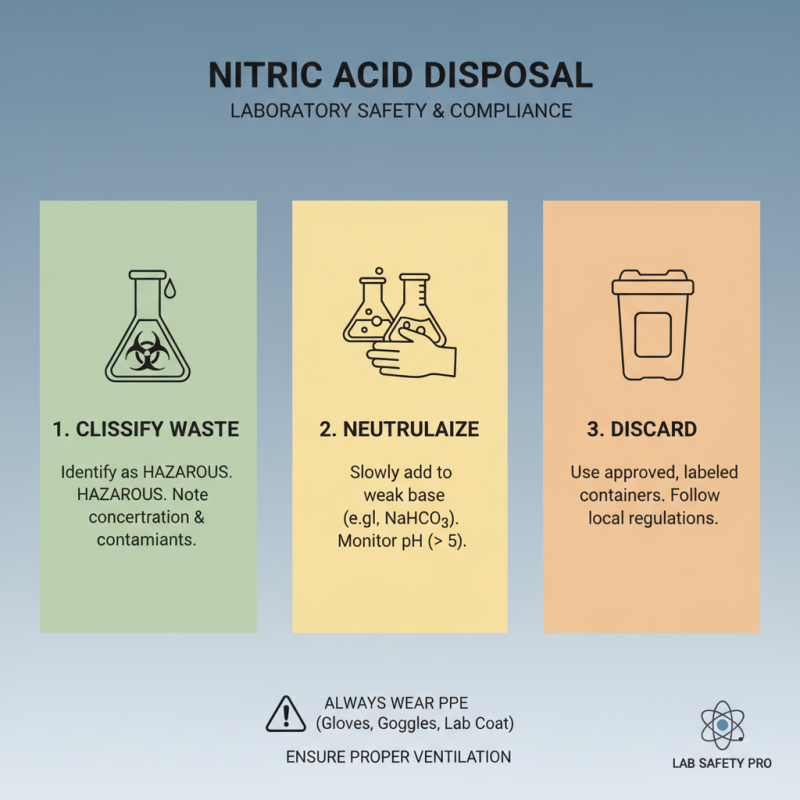

Disposal Guidelines for Nitric Acid Waste in Laboratory Environments

When it comes to handling nitric acid in laboratory environments, proper disposal practices are crucial to ensuring safety and compliance with environmental regulations. Nitric acid is a strong oxidizing agent and can pose serious risks if not correctly neutralized and discarded. The waste produced during experiments must be treated as hazardous, necessitating careful assessment and classification before disposal.

Before disposal, it is essential to identify the concentration and potential contaminants in the nitric acid waste. Neutralization is typically the preferred method for treating nitric acid; this involves carefully mixing the waste with a base, such as sodium bicarbonate or sodium hydroxide, while continuously monitoring pH levels. It is critical to add the neutralizing agent slowly to prevent any exothermic reactions that could lead to splattering or the release of toxic gases. Once neutralized, the resulting solution can often be safely diluted with water and disposed of according to local regulations.

Laboratories must maintain a detailed log of all nitric acid waste, including the volume, concentration, and the methods used for neutralization. This documentation is necessary for regulatory compliance and facilitates proper tracking should any issues arise during the disposal process. It is important to follow institutional guidelines regarding waste disposal and to ensure that personnel handling nitric acid are thoroughly trained in these procedures to minimize risks associated with its use and disposal.

Related Posts

-

How to Get Ultra Pure Chemicals: A Step-by-Step Guide for Beginners

-

Top 5 Chemical Analysis Techniques Every Scientist Should Know

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth

-

5 Best Practices for Chemical Industry Manufacturing Efficiency in 2023

-

10 Essential Tips for Safely Handling Chemistry Chemicals in the Lab

-

How to Choose the Best Chemical Products for Your Business in 2025