Careers

Top High Purity Chemicals for Advanced Applications and Their Benefits?

In the realm of advanced applications, high purity chemicals are indispensable. Dr. Jane Williams, a leading expert in the field, emphasizes, "The quality of high purity chemicals directly impacts innovation and product performance." These chemicals play a crucial role in industries such as pharmaceuticals, electronics, and biotechnology. Their purity ensures that reactions occur as planned, leading to consistent results and the reliability of end products.

High purity chemicals are the backbone of research and development. They enable scientists to explore new compounds and formulations with confidence. For instance, in semiconductor manufacturing, even minor impurities can lead to significant failures. Every detail matters, and the stakes are high. The demand for purity drives suppliers to refine their processes continually.

However, achieving and maintaining high purity levels comes with challenges. Not all suppliers meet the stringent requirements necessary for specialized applications. This inconsistency can hinder progress in critical fields. It raises questions about oversight and the certification processes employed. As we advance, addressing these issues will be vital in harnessing the full potential of high purity chemicals.

Top High Purity Chemicals Explained: What They Are and Why They Matter

High purity chemicals play a critical role in various advanced applications. These substances are ≥99% pure and significantly impact industries like pharmaceuticals, electronics, and aerospace. The demand for high purity chemicals is projected to grow at a CAGR of 6.2% from 2023 to 2028, emphasizing their importance.

Why do high purity chemicals matter? They ensure consistent results and minimize impurities that can compromise product quality. In semiconductor manufacturing, even trace contaminants can lead to failures. Ensuring purity levels exceeds industry standards is essential for reliable performance. For instance, ultrapure water used in production processes can have conductivity levels below 0.055 µS/cm, reflecting its minimal impurity content.

Moreover, sourcing high purity chemicals can pose challenges. The production processes are complex, requiring advanced technologies and strict quality control. Many suppliers struggle to maintain consistent quality over time. This inconsistency can lead to production delays, raising costs. As industries demand higher purity levels, suppliers must adapt or risk losing business. The pursuit of excellence in this field is ongoing, raising questions about future innovations and improvements.

Top High Purity Chemicals for Advanced Applications and Their Benefits

| Chemical Name | Purity Level (%) | Application | Benefits |

|---|---|---|---|

| Aqua Regia | 99.999 | Analytical Chemistry | Excellent solubility for precious metals |

| Hydrochloric Acid | 99.99 | pH Regulation | Highly effective in removing contaminants |

| Sodium Hydroxide | 99.9 | Chemical Manufacturing | Strong base for various reactions |

| Acetic Acid | 99.8 | Food Preservative | Natural preservative effect |

| Methanol | 99.9 | Solvent | Wide applicability in industrial sectors |

| Ethanol | 99.5 | Disinfectant | Effective against a wide range of pathogens |

Key Characteristics of High Purity Chemicals in Advanced Applications

High purity chemicals play a critical role in advanced applications across multiple industries. Their key characteristics include minimal impurities, consistent quality, and precise composition. According to recent industry reports, the demand for these chemicals is projected to grow at a compound annual growth rate (CAGR) of 7.5% by 2025. This highlights the increasing reliance on high purity chemicals in sectors such as pharmaceuticals, semiconductors, and biotechnology.

One striking aspect is their impact on product performance. A study revealed that impurities can affect the efficacy of drug formulations significantly. Even trace levels of contaminants may compromise stability and safety. This is evident in the pharmaceutical industry, where high purity solvents are essential for ensuring effective drug delivery systems. The same principle applies in electronics manufacturing, where the presence of contaminants can lead to defects in semiconductor devices.

However, the path to achieving high purity presents challenges. The production processes often require stringent controls and advanced purification technologies. These processes can be costly and time-consuming. As industries strive for higher standards, reflecting on current production methods is crucial. Continuous improvement is necessary to meet evolving market needs while balancing cost efficiency. The journey toward achieving high purity is complex but essential for advancing technology and developing innovative solutions.

Common Types of High Purity Chemicals Used in Various Industries

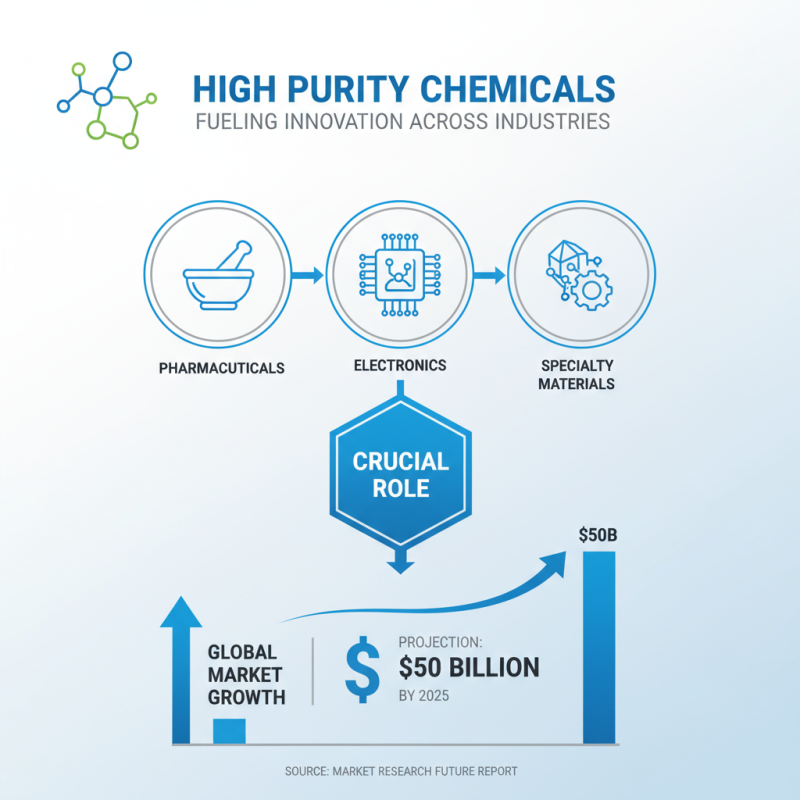

High purity chemicals play a crucial role across various industries. They are integral in sectors like pharmaceuticals, electronics, and specialty materials. For instance, according to a report by Market Research Future, the global market for high purity chemicals is projected to grow significantly, reaching an estimated value of $50 billion by 2025.

In the pharmaceutical industry, high purity solvents and reagents are essential for drug formulation. Their quality directly impacts the efficacy of medications. However, the sourcing of these chemicals can be challenging. Many suppliers often prioritize profit over quality, leading to potential risks.

In electronics, high purity chemicals like photoresists and etchants are vital for producing semiconductors. A slight impurity can lead to defects, significantly affecting performance and yield. A study highlighted that even 1% contamination can decrease product reliability. The focus on quality assurance is essential, yet we see occasional lapses that need addressing. Industries must remain vigilant and invest in enhanced purification processes to mitigate these risks.

Benefits of Using High Purity Chemicals for Enhanced Product Quality

High purity chemicals play a crucial role in enhancing product quality. They are vital in fields like pharmaceuticals, electronics, and food processing. High purity levels reduce contaminants. This directly affects the efficacy and safety of end products. For instance, a single impurity can alter a drug's performance. Therefore, using high purity ingredients ensures reliability.

The benefits of using these chemicals extend beyond product integrity. They often improve manufacturing efficiency. When impurities are minimized, production processes become smoother. This can lead to lower costs in the long run. However, the pursuit of purity can sometimes be challenging. Maintaining rigorous quality control can be resource-intensive.

It's also important to consider supply chain complexities. Sourcing high purity chemicals might limit options. Some manufacturers might need to rethink their strategies. Overall, while the advantages are clear, the journey to achieve high purity is not without obstacles. Producers may need to adapt continuously to meet the market's evolving standards.

Top High Purity Chemicals for Advanced Applications

This bar chart illustrates the importance of using high purity chemicals in various advanced applications. The benefits include enhanced product quality and reliability in sectors such as pharmaceuticals, electronics, and materials science.

Future Trends in High Purity Chemicals and Their Impact on Industries

High purity chemicals are increasingly important in various industries. As technology advances, the demand for these chemicals grows. Sectors like electronics and pharmaceuticals rely heavily on them. These industries require substances that meet strict purity standards. The rise of biotechnology also influences this trend. Scientists need high purity chemicals for research and development. It’s essential for producing reliable results.

Looking to the future, the impact of high purity chemicals will be significant. Innovations will drive better manufacturing processes. This could lead to cost savings and increased sustainability. However, there are challenges. The production process for high purity chemicals can be complex and costly. Smaller companies may struggle to keep up. Also, the focus on sustainability raises questions. What are the best practices? How can the industry minimize waste?

As industries evolve, they must adapt to these changes. Collaboration across sectors will be vital. Companies need to share knowledge and technology. This could lead to breakthroughs in processing and application. The journey is ongoing, and the future of high purity chemicals remains uncertain. Balancing quality, cost, and sustainability will be a constant challenge.

Related Posts

-

How to Choose and Use High Purity Chemicals for Your Experiments

-

Top 10 Industrial Chemical Packaging Solutions for Your Business Needs

-

10 Essential Tips for Safely Handling Chemistry Chemicals in the Lab

-

Top 10 Innovations in Chemical Processing Driving Industry Efficiency in 2023

-

2025 How to Choose the Right Chemical Products for Your Business

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth