Careers

How to Optimize Chemical Manufacturing Processes for Increased Efficiency

In the realm of chemical manufacturing, optimizing processes for increased efficiency is not merely a goal but a necessity for sustainable growth and competitiveness. According to a recent report by the American Chemical Society, the global chemical manufacturing market is projected to reach $5 trillion by 2025, emphasizing the critical need for innovation and efficiency improvements in response to rising demand and environmental regulations. As the industry faces pressure to enhance productivity while minimizing waste, companies are increasingly seeking to implement advanced technologies and lean methodologies to streamline operations.

Dr. Emily Chen, a leading expert in chemical engineering and a prominent figure at the Center for Chemical Process Optimization, states, "Efficiency in chemical manufacturing is not only about cutting costs; it's about creating a sustainable future." Her insights underscore the importance of integrating process optimization techniques that reduce resource consumption and improve yield. By adopting best practices, such as process intensification and digital transformation, firms can unlock significant potential for cost savings and environmental benefits. As the industry continues to evolve, the quest for efficiency in chemical manufacturing remains paramount for driving innovation and sustaining long-term success.

Overview of Chemical Manufacturing Processes

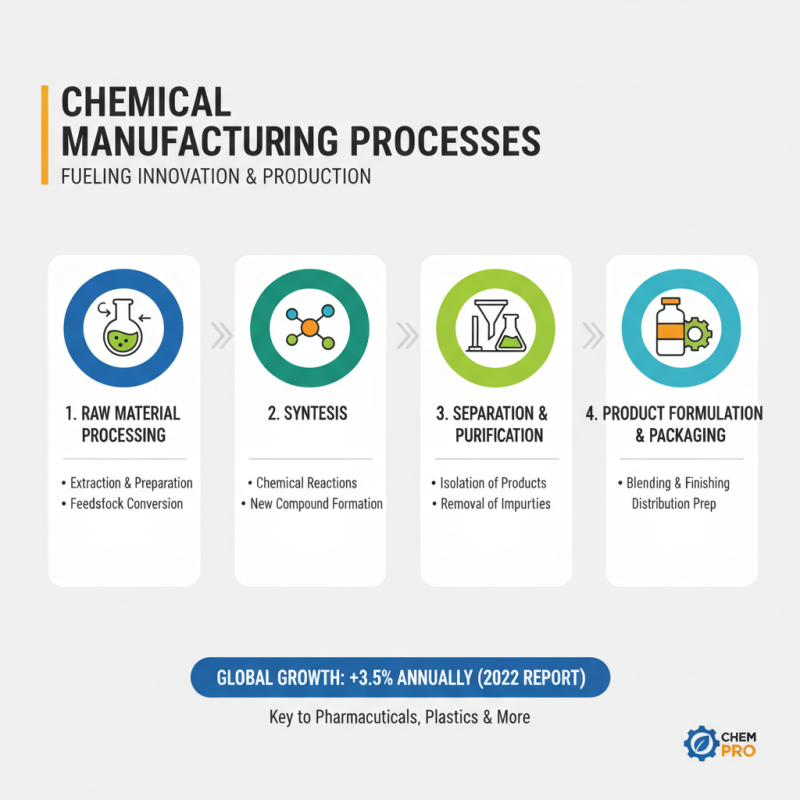

Chemical manufacturing processes play a pivotal role in producing a wide range of products, from pharmaceuticals to materials like plastics. The industry is characterized by various stages, including raw material processing, synthesis, separation, and purification. According to the "2022 Chemical Industry Market Report," global chemical production is projected to grow by 3.5% annually, emphasizing the need for efficiency in these processes to meet rising demand.

To enhance manufacturing efficiency, companies can employ advanced technologies such as real-time monitoring systems and predictive analytics. These technologies allow for the optimization of reaction conditions, improving yield and reducing waste. For instance, a study by the American Institute of Chemical Engineers indicates that using process analytical technology (PAT) can increase process efficiency by up to 25% while ensuring product quality.

**Tip:** Implementing automation in routine tasks can significantly reduce human errors and increase throughput.

Moreover, integrating sustainable practices, such as using renewable energy sources and minimizing hazardous waste, can lead to long-term savings and improved regulatory compliance. As sustainability becomes a crucial focus, firms that adopt eco-friendly approaches in their processes are likely to gain a competitive edge.

**Tip:** Conduct regular audits of energy use and waste management to identify areas where sustainability can be improved.

Identifying Key Efficiency Metrics in Chemical Production

Identifying key efficiency metrics in chemical production is crucial for optimizing manufacturing processes. One of the primary metrics is yield, which measures the amount of product produced relative to the raw materials used. High yield indicates effective conversion of inputs into desired outputs, reflecting both the efficiency of chemical reactions and the effectiveness of process controls. Monitoring yield helps identify areas for improvement, such as optimizing reaction conditions, enhancing catalyst performance, or reducing waste.

Another important metric is cycle time, which represents the total time taken to complete one production cycle from start to finish. Reducing cycle time can lead to increased throughput and improved responsiveness to market demands. By analyzing cycle time across different phases of production, manufacturers can pinpoint bottlenecks and streamline operations. This can involve adopting automation technologies, improving equipment reliability, or enhancing workforce training to ensure that each step in the process contributes to overall efficiency.

Finally, energy consumption is a critical metric that affects both operational costs and environmental impact. By measuring energy usage throughout the production cycle, manufacturers can identify energy-intensive processes that may benefit from optimization. This could involve implementing energy-efficient technologies, recycling waste heat, or transitioning to renewable energy sources. By focusing on these key efficiency metrics—yield, cycle time, and energy consumption—chemical manufacturers can significantly enhance their production processes and achieve greater sustainable performance.

Techniques for Process Optimization in Chemical Manufacturing

In the chemical manufacturing industry, optimizing processes is crucial for enhancing efficiency and reducing operational costs. One effective technique is the application of Lean Manufacturing principles, which focus on eliminating waste and improving workflow. By mapping out the entire production process, manufacturers can identify bottlenecks and streamline operations. This practice not only increases the efficiency of resource use but also boosts overall productivity, allowing for quicker response times to market demands.

Another key technique in process optimization is the implementation of advanced process control (APC) systems. These systems utilize real-time data and analytics to regulate production conditions, ensuring that processes operate within optimal parameters. By continuously monitoring key performance indicators, such as temperature and pressure, APC systems enable manufacturers to maintain consistency in product quality. Furthermore, the integration of predictive maintenance strategies can prevent unexpected downtimes, thereby increasing reliability and output.

Investing in employee training also plays a vital role in optimizing chemical manufacturing processes. Equipping staff with the necessary skills to understand and implement optimization techniques fosters a culture of continuous improvement. Engaged employees are more likely to contribute innovative ideas and identify inefficiencies, leading to a more agile production environment. By combining technology and human expertise, chemical manufacturers can achieve significant gains in efficiency and sustainability.

Implementing Technology and Automation for Improved Efficiency

The integration of technology and automation in chemical manufacturing processes is crucial for achieving enhanced operational efficiency. Recent industry reports indicate that adopting advanced technologies can lead to efficiency improvements of up to 30% in production lines. For example, the use of robotics in material handling has streamlined workflows, significantly reducing downtime and labor costs. According to a study published by the International Society for Automation, companies implementing automated systems report a 25% reduction in production cycle times.

To maximize the benefits of automation, manufacturers should consider upgrading their existing equipment with smart technology. This includes using sensors and IoT devices that can continuously monitor performance and provide real-time data analytics. By interpreting this data effectively, companies can identify bottlenecks and make data-driven decisions to optimize their processes.

**Tips:** Start with small pilot projects to gauge the impact of automation before large-scale implementation. Ensure that staff is trained to work alongside new technologies, as their insights can be invaluable in fine-tuning processes. Another important aspect is to maintain compliance with safety regulations while integrating tech solutions, ensuring that efficiency gains do not compromise safety standards.

How to Optimize Chemical Manufacturing Processes for Increased Efficiency - Implementing Technology and Automation for Improved Efficiency

| Parameter | Before Optimization | After Optimization | Improvement (%) |

|---|---|---|---|

| Production Yield | 85% | 92% | 8.24% |

| Energy Consumption (kWh) | 1200 | 900 | 25% |

| Raw Material Cost ($) | $10,000 | $8,500 | 15% |

| Process Downtime (hours) | 50 | 20 | 60% |

| Overall Equipment Effectiveness (OEE) | 65% | 78% | 20% |

Continuous Improvement Strategies for Sustaining Production Gains

To sustain production gains in chemical manufacturing, the implementation of continuous improvement strategies is essential. These strategies focus on regularly evaluating and refining processes to enhance efficiency and reduce waste. One effective approach is adopting Lean Manufacturing principles, which emphasize streamlining operations by identifying and eliminating non-value-adding activities. This not only optimizes workflow but also fosters a culture of innovation, encouraging employees to contribute ideas for process enhancements.

Another crucial aspect is the integration of data-driven decision-making. By leveraging advanced analytics and real-time monitoring systems, manufacturers can gain valuable insights into their operations. This enables them to identify bottlenecks and inefficiencies promptly. Furthermore, employing techniques such as Six Sigma can significantly enhance quality control by minimizing variability in production processes. Through ongoing training and development programs, teams can be equipped with the skills necessary to implement these methodologies effectively, ensuring sustained improvements and increased production capacity over time.

Related Posts

-

How to Choose the Best Chemical Products for Your Business in 2025

-

10 Essential Tips for Safely Handling Chemistry Chemicals in the Lab

-

Top 10 Essential Chemicals You Need to Know for Everyday Use

-

How to Choose and Use High Purity Chemicals for Your Experiments

-

Top 10 Innovations in Chemical Processing Driving Industry Efficiency in 2023

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth