Careers

How to Optimize Manufacturing Chemical Processes for Better Efficiency

The optimization of manufacturing chemical processes is a critical factor in enhancing operational efficiency and economic sustainability within the chemical industry. According to a report by the American Chemical Society, chemical manufacturing accounts for approximately 14% of the world's fossil fuel consumption and emits around 7% of global greenhouse gases. Given the increasing pressure on organizations to minimize their environmental footprint while maximizing productivity, optimizing chemical processes has never been more vital.

Furthermore, a study published by the World Economic Forum highlights that the adoption of advanced technologies such as process automation and data analytics can lead to efficiency improvements of up to 30%. By focusing on key areas such as waste reduction, energy efficiency, and process integration, manufacturers can significantly lower production costs while maintaining high-quality outputs. As the demand for sustainable practices continues to rise, the ability to effectively streamline manufacturing chemical processes will not only enhance profitability but also contribute to a more resilient and sustainable industry.

Understanding the Importance of Efficiency in Chemical Manufacturing

Efficiency in chemical manufacturing is paramount for several reasons, impacting both cost-effectiveness and environmental sustainability. In a sector where margins can be thin, optimizing processes can lead to significant savings in raw material usage, energy consumption, and operational expenses. By embracing efficient methodologies, manufacturers can reduce waste and streamline operations, ultimately enhancing their competitiveness in a global market.

Furthermore, enhancing efficiency in chemical processes contributes to a reduced environmental footprint. As regulations around emissions and waste management become increasingly stringent, companies are compelled to adopt greener practices. This not only helps comply with legal requirements but also appeals to a growing base of environmentally conscious consumers. Employing advanced technologies, such as process automation and real-time monitoring, allows for continuous adjustments that can improve production rates while minimizing the release of hazardous substances. In essence, a commitment to efficiency in chemical manufacturing is not only a strategic business move but also a vital step towards sustainable industrial practices.

How to Optimize Manufacturing Chemical Processes for Better Efficiency

| Process Step | Efficiency Factor | Current Performance (%) | Optimized Performance (%) | Potential Improvement (%) |

|---|---|---|---|---|

| Mixing | Agitation Speed | 85 | 95 | 10 |

| Heating | Heat Transfer Efficiency | 75 | 90 | 15 |

| Reactor Operation | Catalyst Efficiency | 80 | 95 | 15 |

| Separation | Separation Time | 70 | 88 | 18 |

| Quality Control | Inspection Efficiency | 90 | 98 | 8 |

Identifying Key Performance Indicators for Chemical Processes

Identifying key performance indicators (KPIs) is essential for optimizing manufacturing chemical processes and enhancing overall efficiency. KPIs serve as quantifiable metrics that provide insights into the performance and reliability of chemical operations. Common KPIs include yield, cycle time, energy consumption, and waste generation. By closely monitoring these indicators, manufacturers can pinpoint areas that require improvement, thereby enabling more informed decision-making and resource allocation.

To effectively implement KPIs in chemical manufacturing, it is crucial to establish clear benchmarks and performance expectations. For instance, tracking yield percentages can help determine how effectively raw materials are converted into finished products. Additionally, cycle time analysis can reveal bottlenecks in the production process, allowing for targeted interventions. Energy consumption metrics not only highlight areas for cost savings but also foster a commitment to sustainable practices. By regularly reviewing these KPIs, manufacturers can ensure continuous improvement, align operational objectives with strategic goals, and ultimately boost efficiency and productivity in their chemical processes.

Key Performance Indicators for Chemical Processes

This bar chart represents the efficiency of various chemical manufacturing processes based on key performance indicators over the last year. The selected KPIs include Yield, Cycle Time, and Energy Consumption, showing the effectiveness of process optimization strategies.

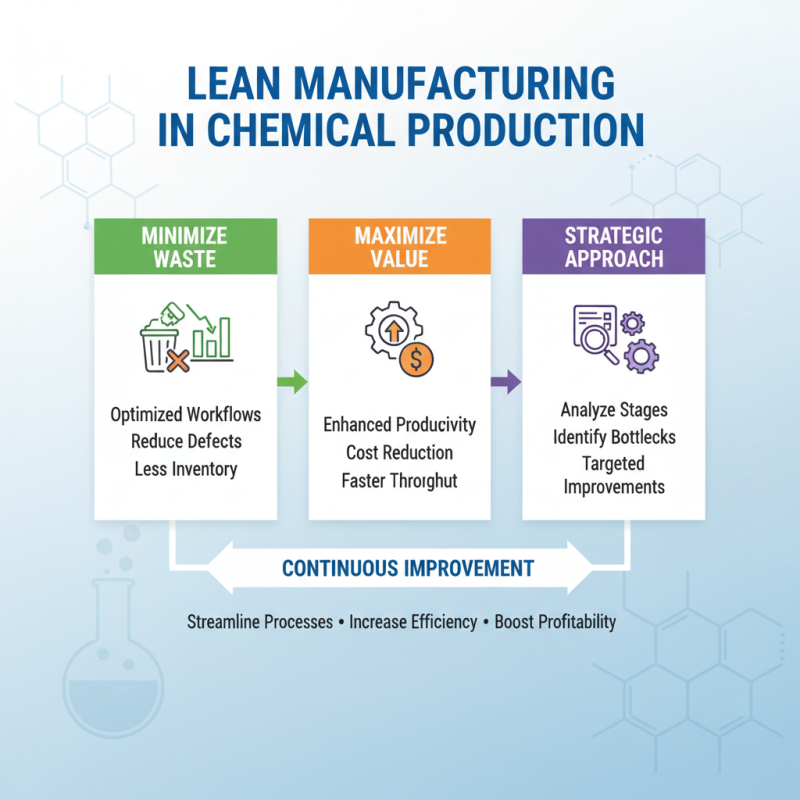

Implementing Lean Manufacturing Principles in Chemical Production

Implementing Lean Manufacturing Principles in chemical production involves a strategic approach to minimize waste while maximizing value throughout the manufacturing process. Lean principles focus on optimizing workflows and eliminating non-value-added activities, which can significantly enhance productivity in chemical manufacturing. By closely analyzing each stage of production, companies can identify bottlenecks and areas of inefficiency, allowing for targeted improvements that streamline processes and reduce costs.

One key aspect of lean manufacturing is the application of the 5S methodology—Sort, Set in order, Shine, Standardize, and Sustain. This framework helps create a more organized and efficient workspace, leading to improved safety and morale among employees. Moreover, adopting a culture of continuous improvement encourages teams to regularly assess their practices and implement innovative solutions. This can involve cross-training employees to enhance flexibility or employing real-time data tracking systems to monitor performance metrics, ensuring that all operations work seamlessly towards optimal efficiency. By embedding these lean practices into the core of chemical production, manufacturers can not only enhance operational efficiency but also ensure their processes are sustainable and adaptive to market changes.

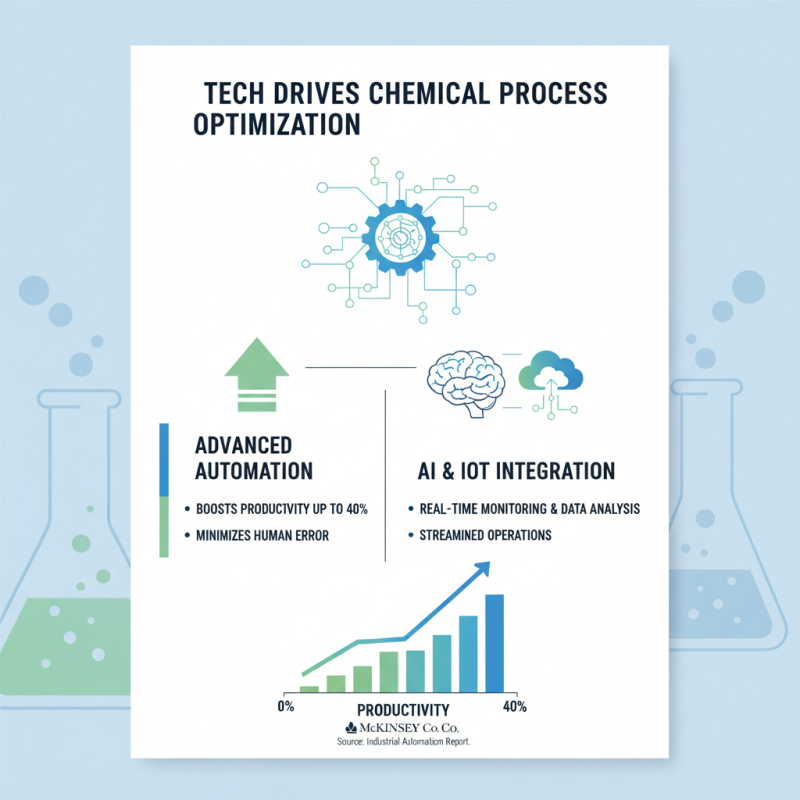

Leveraging Technology for Process Automation and Optimization

The optimization of manufacturing chemical processes is increasingly reliant on technology, particularly in the realm of process automation and optimization. According to the McKinsey & Company report on industrial automation, companies that implement advanced automation technologies can boost productivity by up to 40%. This substantial gain reflects the efficiency that comes with automating repetitive tasks, minimizing human error, and accelerating production cycles. The integration of technologies such as the Internet of Things (IoT) and machine learning can significantly enhance process monitoring and data analysis, allowing for real-time adjustments that further streamline operations.

Tips: Invest in IoT sensors to gather real-time data on equipment performance, as this can help in preemptive maintenance and reduce downtime. Utilizing predictive analytics can also guide decision-making processes, ensuring that resources are allocated effectively and waste is minimized.

Moreover, automation not only improves operational efficiency but also supports sustainability initiatives. The World Economic Forum indicates that automation can reduce material waste by up to 30% in chemical manufacturing. By leveraging automated systems to monitor and control chemical reactions with greater precision, manufacturers can use fewer resources and reduce environmental impact. Emphasizing these technologies fosters a competitive edge while aligning with global sustainability goals.

Tips: Evaluate existing processes to identify bottlenecks and areas where automation can lead to waste reduction. Engaging employees in training programs can also enhance the transition to automated systems, ensuring that staff can leverage new technologies effectively.

Continuous Improvement Strategies for Sustained Manufacturing Efficiency

Continuous improvement is essential for optimizing manufacturing chemical processes and achieving sustained operational efficiency. Implementing methodologies such as Lean Manufacturing, Six Sigma, and Kaizen can significantly enhance productivity by identifying waste and inefficiencies in processes. These approaches focus on creating value for customers while minimizing resources, which ultimately leads to cost savings and faster production times.

Tips for continuous improvement include regularly analyzing production data to uncover trends and areas for enhancement. Foster a culture of open communication, encouraging team members to suggest improvements based on their day-to-day experiences. Additionally, consider setting up cross-functional teams that can collaborate to identify and solve process-related challenges from multiple perspectives.

Another vital element of continuous improvement is employee training and development. Investing in skills enhancement not only boosts motivation but also equips staff with the latest techniques and methodologies. Encourage ongoing education through workshops, seminars, and knowledge-sharing sessions to keep your workforce informed and engaged, ultimately driving further improvements in efficiency.

Related Posts

-

Top 10 Tips for Choosing the Right Manufacturing Chemicals for Your Business

-

5 Best Practices for Chemical Industry Manufacturing Efficiency in 2023

-

2025 How to Choose the Right Chemical Products for Your Business

-

How to Choose and Use High Purity Chemicals for Your Experiments

-

10 Essential Tips for Safely Handling Pure Nitric Acid in Laboratories

-

How to Choose the Right Specialty Chemicals for Your Business Needs