Careers

Top 10 Tips for Choosing the Right Manufacturing Chemicals for Your Business

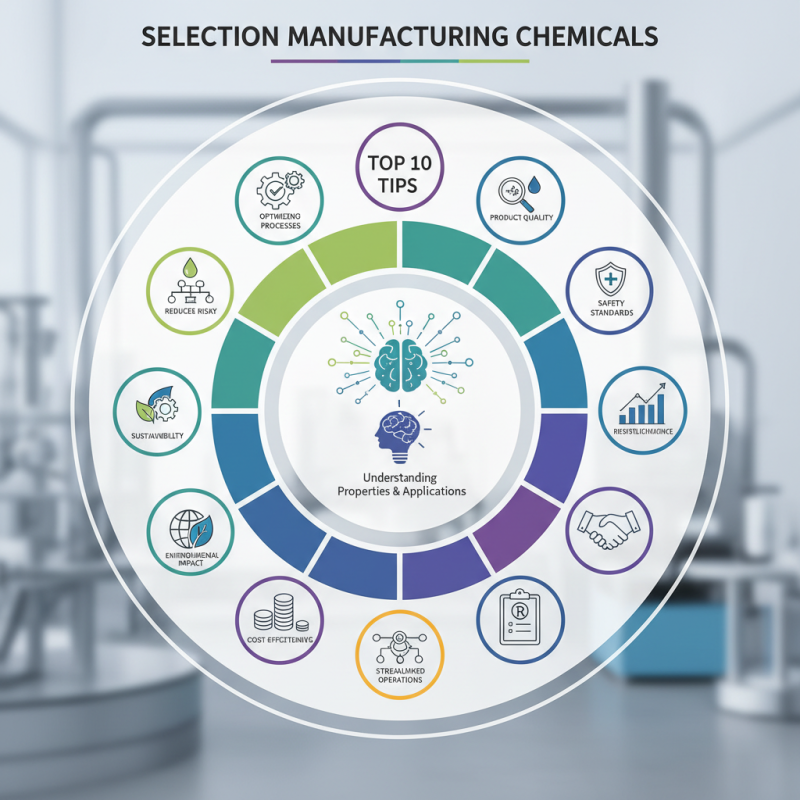

Selecting the right manufacturing chemicals is crucial for optimizing processes, ensuring product quality, and maintaining safety standards in any industrial operation. According to John Smith, a renowned expert in the manufacturing chemical industry, "Choosing the right chemicals can dramatically influence production efficiency and end product quality." His insights highlight not only the importance of selecting appropriate materials but also the necessity of understanding their properties, applications, and potential impacts on both productivity and sustainability.

As manufacturing industries continue to evolve, the demand for precision and efficiency grows stronger, making the selection of the correct manufacturing chemicals more significant than ever. Various factors play a role in this decision-making process, such as regulatory compliance, environmental impact, and cost-effectiveness. By carefully assessing these elements, businesses can streamline their operations and adopt best practices, leading to enhanced performance and reduced risks. In this article, we will explore the top 10 tips for choosing the right manufacturing chemicals tailored to your business needs.

Understanding the Role of Manufacturing Chemicals in Production Processes

In modern production processes, manufacturing chemicals play a crucial role in enhancing efficiency and ensuring product quality. These chemicals serve various functions, including acting as solvents, catalysts, and stabilizers, which contribute to the reliability and performance of the final product. Understanding their specific roles and how they interact with other materials in the production line can significantly impact operational outcomes. For instance, the choice of a solvent can affect the viscosity of a mixture, influencing the ease of processing and the characteristics of the end product.

Moreover, the right manufacturing chemicals can lead to improved safety and compliance with environmental regulations. Selecting chemicals with lower toxicity and environmental impact not only protects workers but also aligns with sustainability goals. This is increasingly important as industries strive to adopt greener practices. Properly evaluating the role of chemicals in production processes can facilitate innovation while addressing safety and regulatory challenges, ultimately supporting a business's commitment to social responsibility.

Identifying Specific Chemical Needs for Your Manufacturing Operations

Identifying specific chemical needs for your manufacturing operations is a crucial step in enhancing productivity and ensuring product quality. Begin by conducting a thorough assessment of your production processes to determine the types of chemicals that are essential. This involves analyzing every stage of manufacturing to understand the chemical interactions and reactions that are necessary for optimal performance. Engage with your production team to gather insights into the challenges they face, as their firsthand experience can highlight specific chemical requirements that may not be immediately apparent.

Moreover, consider the compatibility of the chemicals with your existing equipment and the nature of your materials. Different manufacturing processes may require various chemical properties, such as viscosity, reactivity, or stability under specific conditions. Establishing a clear understanding of your operational parameters will guide you in selecting the right chemicals that not only meet performance criteria but also enhance worker safety and environmental compliance. Prioritizing a systematic approach to identify these needs will ultimately lead to improved operational efficiency and a more controlled manufacturing environment.

Evaluating Supplier Credentials and Chemical Quality Standards

When choosing manufacturing chemicals for your business, evaluating supplier credentials is crucial in ensuring that you partner with a reliable source. Start by examining the supplier’s track record in the industry. Look for certifications and memberships in relevant trade associations, which can indicate a commitment to quality and compliance with industry standards. Additionally, consider seeking references from other businesses that have previously engaged with the supplier to gauge their reliability and service quality.

Equally important is assessing the quality standards of the chemicals being offered. Review the supplier's quality control processes and ask for documentation, such as safety data sheets (SDS) and certificates of analysis (CoA). These documents can provide insights into the chemical's composition, safety measures, and performance characteristics. Additionally, inquire about their testing methods and any third-party audits they may have undergone, as this can further affirm the quality of their products. Ensuring that the chemicals meet both your operational requirements and regulatory standards is essential for maintaining both product integrity and workplace safety.

Considering Regulatory Compliance and Safety Measures

When selecting manufacturing chemicals for your business, regulatory compliance and safety measures should be at the forefront of your decision-making process. Understanding the legal framework that governs the use of chemicals in your industry is essential to avoid potential fines and disruptions. Familiarize yourself with local, national, and international regulations, such as those provided by environmental protection agencies and occupational safety administrations. Ensuring that the chemicals you choose are compliant with these regulations will not only safeguard your business but also promote a culture of safety among your workforce.

In addition to regulatory compliance, prioritize the safety measures associated with the handling and storage of chemicals. Conduct a thorough risk assessment to identify potential hazards and implement appropriate controls. This includes providing adequate training for employees, ensuring that they are informed about safe practices and emergency protocols. Opt for chemicals that come with comprehensive safety data sheets (SDS), which outline the properties of the chemicals and any associated risks. By focusing on compliance and safety, you will create a safer working environment and enhance the overall operational efficiency of your manufacturing processes.

Assessing Cost-effectiveness and Long-term Supply Chain Reliability

When selecting manufacturing chemicals for your business, assessing cost-effectiveness and long-term supply chain reliability should be at the forefront of your decision-making process. A thorough evaluation of the chemicals' costs can provide insights into not just the initial purchase price but also the potential for savings over time due to efficiency and performance. It’s essential to calculate the total cost of ownership, including disposal, storage, and regulatory compliance costs, which may significantly influence your bottom line.

One vital tip is to establish clear communication with your suppliers. This dialogue ensures that you can stay informed about any fluctuations in availability and prices. Additionally, consider working with suppliers who demonstrate a commitment to sustainability, as they are more likely to have stable operations and transparent supply chains. Another important factor is to assess the flexibility of your suppliers; a reliable partner should be able to adapt to changes in demand without compromising quality or timeliness.

Finally, conduct regular reviews and comparisons of your chemical suppliers to ensure that you are consistently getting the best value. Long-term relationships often lead to better pricing and preferred access to products, but it’s crucial to reevaluate these partnerships periodically. By remaining proactive in assessing both cost-effectiveness and supply chain reliability, you can safeguard your operations against unforeseen disruptions while optimizing your manufacturing processes.

Related Posts

-

2025 How to Choose the Right Chemical Products for Your Business

-

Top 10 Innovations in Chemical Processing Driving Industry Efficiency in 2023

-

2025 How to Choose the Best Industrial and Chemical Solutions for Your Business

-

5 Best Practices for Chemical Industry Manufacturing Efficiency in 2023

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth

-

How to Choose the Right Specialty Chemicals for Your Business Needs