Careers

How to Get Ultra Pure Chemicals: A Step-by-Step Guide for Beginners

In the rapidly advancing field of chemistry, the demand for ultra pure chemicals has surged significantly, driven by the increasing precision requirements in industries such as pharmaceuticals, biotechnology, and electronics. According to a report by Grand View Research, the global ultra pure chemicals market is expected to reach USD 8.3 billion by 2027, highlighting a compound annual growth rate (CAGR) of 6.4% from 2020 to 2027. This growth is primarily fueled by the critical need for high-quality raw materials in R&D and manufacturing processes, where even minute impurities can lead to significant deviations in outcomes.

Dr. Emily Hartmann, a renowned expert in analytical chemistry, emphasizes the importance of sourcing ultra pure chemicals with utmost care, stating, "The integrity of your results is directly proportional to the purity of your reagents. In today's precision-driven landscape, cutting corners on chemical purity is not an option." As beginners embark on their journey to procure ultra pure chemicals, understanding the right methodologies and quality benchmarks is essential to ensure both compliance and efficacy in their research or industrial applications. This step-by-step guide aims to empower novices with actionable insights and resources to navigate the complexities of acquiring ultra pure chemicals, ensuring that they are well-equipped to meet the stringent demands of their respective fields.

Understanding Ultra Pure Chemicals and Their Importance

Ultra pure chemicals are essential in various industries, including pharmaceuticals, semiconductors, and research laboratories. These chemicals are characterized by their high level of purity, typically exceeding 99.99%, which is crucial for ensuring the accuracy and reliability of experimental results and product efficacy. According to a report by the International Journal of Pure and Applied Chemistry, impurities in chemicals can significantly alter reactions, leading to inconsistent results and potentially expensive product failures. This underlines the importance of using ultra pure chemicals in processes where precision is paramount.

The production of ultra pure chemicals involves meticulous purification techniques, such as distillation, recrystallization, and ion exchange. These processes not only remove contaminants but also ensure that the chemicals meet strict industry standards. The global market for ultra pure chemicals is projected to grow significantly, with the Semiconductor Industry Association estimating that the demand for ultra pure water alone will reach 2.7 billion liters annually by 2025. This growth highlights the increasing reliance on ultra pure chemicals across various sectors, emphasizing their critical role in advancing technology and improving product quality.

How to Get Ultra Pure Chemicals: A Step-by-Step Guide for Beginners - Understanding Ultra Pure Chemicals and Their Importance

| Chemical Name | Purity Level (%) | Common Uses | Recommended Storage |

|---|---|---|---|

| Sodium Chloride | 99.9 | Lab Reagents, Food Additives | Cool, Dry Place |

| Acetic Acid | 99.5 | Solvent, Chemical Synthesis | Refrigerated |

| Ethanol | 99.9 | Disinfectant, Solvent | Cool, Dry Place |

| Hydrochloric Acid | 37 | pH Adjustments, Chemical Manufacturing | Cool, Dry Place, Away from Incompatible Materials |

| Potassium Nitrate | 99 | Fertilizers, Food Preservation | Cool, Dry Place |

Identifying Sources for Ultra Pure Chemicals

When seeking ultra pure chemicals, the first step is identifying reliable sources that meet rigorous purity standards. It is crucial to approach suppliers that specialize in high-purity chemicals, typically used in advanced research, pharmaceuticals, and semiconductor manufacturing. Start by exploring academic institutions or research facilities, as they often maintain a network of reputable suppliers and might provide insights into the best sources for ultra pure materials. Collaborating with experienced chemists can also lead to discovering lesser-known suppliers that prioritize quality.

Additionally, consider checking industry publications and scientific journals that often feature articles on the best practices and suppliers for high-quality chemicals. Networking at conferences or workshops can also connect you with professionals who can share their experiences and recommendations on sourcing ultra pure chemicals. Moreover, the online marketplace for chemicals may have specialized vendors that provide detailed specifications about their products, ensuring compliance with the purity levels required for your applications. Always verify the supplier’s accreditation and quality assurance processes to ensure you are obtaining the highest possible purity.

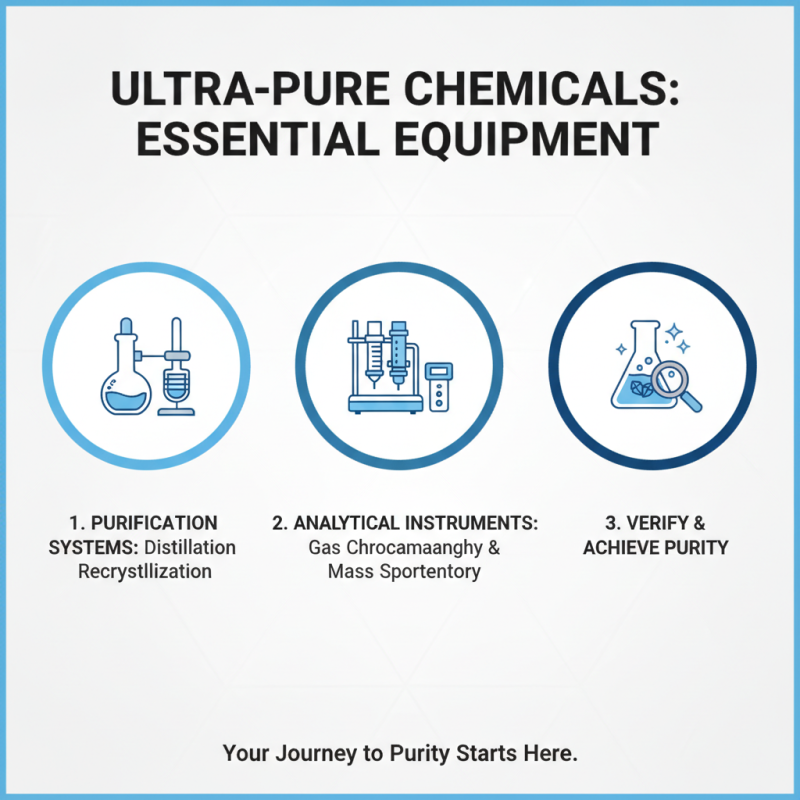

Essential Equipment and Tools for Purification

When embarking on the journey to obtain ultra-pure chemicals, having the right equipment and tools is essential. First and foremost, you’ll need a high-quality purification system, such as a distillation apparatus or a recrystallization setup. These tools effectively remove impurities from your chemicals, allowing you to achieve the purity levels required for your projects. Additionally, investing in analytical instruments like gas chromatography or mass spectrometry can help verify the purity of the chemicals before you use them.

Tips: Always ensure that your glassware is thoroughly cleaned and dried before use, as even minor residues can contaminate your results. Utilize vacuum filtration setups when dealing with particulate matter, ensuring a clearer end product.

Another crucial component is protective gear, which should not be overlooked. Wearing gloves, goggles, and lab coats will not only keep you safe from potential hazards but also prevent contamination of your chemicals. Furthermore, a controlled environment, like a fume hood or a clean room, can minimize external contaminants that may compromise the purity of your work.

Tips: Regularly calibrate your measuring instruments to maintain accuracy, and keep an organized workspace to avoid mix-ups and cross-contamination. Taking these preventive measures will greatly enhance your success in achieving ultra-pure chemicals.

Step-by-Step Methods for Achieving Ultra Pure Chemicals

Achieving ultra-pure chemicals is a critical process in various industries, ranging from pharmaceuticals to electronics. The purity standards often exceed 99.99%, necessitating meticulous methods and procedures. One effective approach involves recrystallization, where a solvent is used to dissolve impurities, followed by careful cooling to allow for the formation of pure crystals. This method has been shown to retain up to 98% of the original product quality, as highlighted in a recent study published by the American Chemical Society.

Another valuable technique for obtaining ultra-pure chemicals is distillation, leveraging differences in boiling points to separate components. For instance, fractional distillation can achieve purities of 99.999%, particularly beneficial in the production of solvents or essential reagents for scientific research. The European Journal of Applied Chemistry reports that advances in equipment and methodology have made it feasible for laboratories to achieve higher purity levels than ever before.

Tips: Always ensure proper calibration of your equipment before beginning any purification process, as even minor discrepancies can lead to lower purity levels. Additionally, using high-quality reagents from trusted suppliers can significantly reduce the risk of contamination during experiments. When working with sensitive compounds, conducting your purification procedures in a controlled environment, such as a fume hood, can also help maintain the integrity of your chemicals.

Safety Precautions and Best Practices in Chemical Handling

When handling chemicals, safety precautions are paramount to ensure a secure and efficient working environment. According to the Occupational Safety and Health Administration (OSHA), nearly 650,000 workers are exposed to hazardous chemicals in the workplace each year. Thus, it is essential for beginners to familiarize themselves with personal protective equipment (PPE), including gloves, goggles, and lab coats, which serve as the first line of defense against chemical exposure.

Moreover, understanding the proper handling and storage protocols for ultra-pure chemicals is critical. The National Institute for Occupational Safety and Health (NIOSH) suggests utilizing well-ventilated areas and employing fume hoods when working with volatile substances to minimize inhalation risks. Additionally, appropriate labeling and segregation of chemicals not only facilitate safety but also comply with regulatory standards, emphasizing the importance of adhering to Material Safety Data Sheets (MSDS) for each substance being utilized. This practice helps in quickly identifying potential hazards and necessary first-aid measures in case of accidental exposure, thus promoting a safer laboratory environment for everyone involved.

Ultra Pure Chemicals Production Process

This chart illustrates the time taken for each step involved in the production of ultra pure chemicals. Understanding these steps helps ensure safety and efficiency in chemical handling.

Related Posts

-

2025 Top 5 Innovative Chemical Solutions for Sustainable Industry Growth

-

5 Best Practices for Chemical Industry Manufacturing Efficiency in 2023

-

How to Choose the Right Specialty Chemicals for Your Business Needs

-

10 Essential Tips for Safely Handling Chemistry Chemicals in the Lab

-

2025 How to Choose the Best Industrial and Chemical Solutions for Your Business

-

How to Choose the Best Chemical Products for Your Business in 2025